hardness tester hrc|roundness correction factors chart : makers • Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more

Ao clicar na confirmação abaixo, você declara expressament.

{plog:ftitle_list}

Veja o Bicho Atrasado para fazer o seu jogo do dia, o melhor .

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use . See more

The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See more

The Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more• International (ISO)• US standard (ASTM International) See more

• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See moreThe most common Rockwell method in practice is HRC. In principle, ball indenters are used for the hardness tests on softer materials and diamond indenters for testing harder materials. The diamond would destroy softer . The most commonly used portable Leeb hardness tester can convert Leeb (HL) measurements into Brinell (HB), Rockwell (HRC), Vickers (HV), and Shore (HS) hardness. Or use the Leeb principle to directly measure .

roundness correction factors chart

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the . Confused about Rockwell and Brinell hardness testing? Our guide explains the differences between the two methods and offers a conversion chart to switch from one to the other.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

rockwell superficial hardness tester

The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth .

A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a .Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and .

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. . Example 1: A regular Rockwell hardness method (HRC) 45 HRC. The number 45 represents the hardness value of the material. HR is the abbreviation for Rockwell hardness.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .Hardness testing is widely used in a multitude of industries and plays particular significance in structural, aerospace, automotive, quality control, failure analysis, and many other forms of . by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals. With the increasing use of materials other than common steel

Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . Rockwell Hardness Values: Very Hard Steel: HRC 55 to HRC 66: Axes: HRC 45 to HRC .Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .

1/16" Carbide Ball Indenter Hardness test Block 60 HRC Hardness test Block 60 HRC AC Adapter Hardness test Block 30 HRC Hardness test Block 30 HRC Users Manual Hardness test Block 90 HRBW Hardness test Block 90 HRBW Vinyl Cover Hardness test Block 65 HR30N Accessory Box Hardness test Block 70 HR30TW Level Scale Hardness HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a relatively accurate conversion relationship between hardness and strength is needed in production.. Experience has shown that there is . Dalam pengukuran kekerasan material dengan Digital Rockwell Hardness Tester, pemilihan skala antara HRC dan HRB penting untuk aplikasi yang berbeda. Skala HRC cocok untuk logam keras dan tahan aus, sementara HRB lebih sesuai untuk material lunak dengan kekuatan moderat. Selebihnya, teknologi digital juga memiliki fungsi dalam meningkatkan .

micro vickers hardness tester

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . HRC – Known as “Rockwell C,” a 150 kgf load is .

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .This rebound hardness tester features a universal D impact device and is capable of displaying measurements in 7 hardness scales. The R9030 features a rechargeable battery, internal memory to store up to 350 measurements and software to further analyse saved data. . Hardness Scales: Rockwell (HRA, HRB, HRC) Brinell (HB) Leeb (HLD) Vickers (HV .The hardness tester products you will find at PCE Instruments (PCE) are used for determining surface hardness. Each hardness tester uses a standard method of measurement. The measuring principles of most hardness tester devices are based on either the penetration of a diamond. . Testing of HRC, HRB, HV, HB, HSD .

&\boxed{HRC, HRA =100-\frac{h}{0.002}} ~~~~~\text{Rockwell hardness for diamond cone} \[5px] \label{rockwellhaertewert_2} . The advantage of Rockwell hardness testing is the relatively short testing time and good automation capability, as the measured values are determined directly from the indentation depth without optical measurement under .

Analog rockwell hardness tester, hrc, model name/number: 250. Digital shore hardness tester, model name/number: mextech, 0. White lcd load cell based touch screen rockwell cum superfic. Digital asi rock-150t automatic rockwe:ll .The Portable Steel Hardness Tester measures the hardness of metals in the range of 20 to 65 HRC on the equivalent Rockwell C Scale. The instrument is fully portable and easy to use. It can easily be carried anywhere an accurate .

Dalam konteks ini, Hardness Tester Instrument menjadi alat uji yang tak tergantikan dalam menentukan kekerasan material. Alat Laboratorium. . diukur dalam skala Rockwell C (HRC) yang sering digunakan untuk .

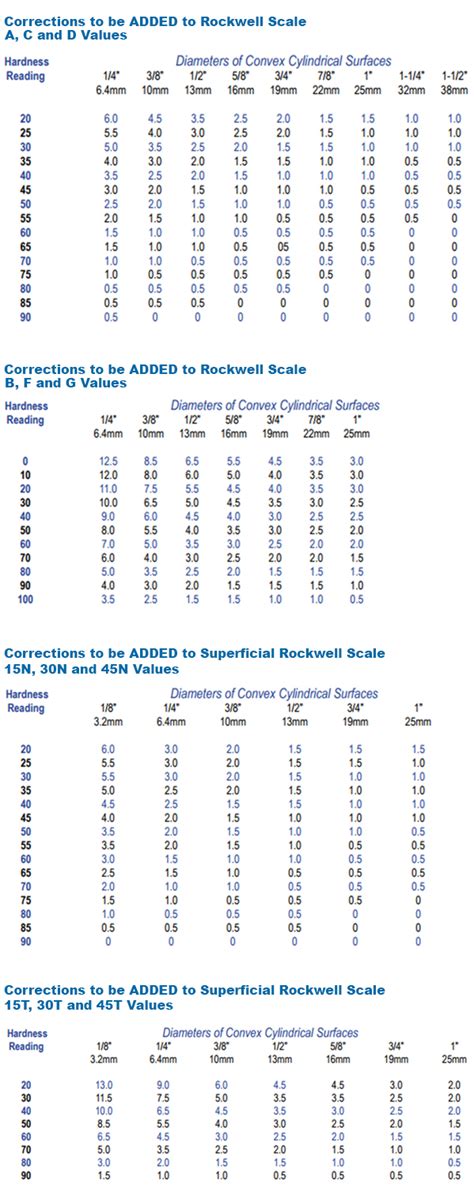

Find the roundness correction factors for Rockwell testing and Rockwell superficial testing here. Download as PDF or get the roundness corrections right away. There are 30 different Rockwell scales with the majority of applications covered by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals. With the increasing use of materials other than common steel and brass, as well as requirements to test thin materials and sheet steel, a basic knowledge of the factors that must .

Portable Leeb Hardness Tester Kit with Test Block,Hardness Testing Equipment,Rockwell Metal Hardness Meter Durometer for Steel,Aluminum Alloy,Copper,7-in-1 HL, HV, HB, HRC, HRB, HRA, HS 7 8.98 $ 198 . 98Affri Hardness testers for Rockwell, Brinell and Vickers. Best portable or benchtop machines to test hardness in compliance with ASTM and ISO. +39 0332 201 533. [email protected]. Home; . HRC + HB UP TO 187.5 KGF COMPACT SIMPLE. HRC + HB UP TO 187.5 KGF. COMPACT. SIMPLE. SHORE / IRHD. HARDNESS TESTERS.

Wilson Rockwell hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable Rockwell test blocks available. . HRC Scale; Certified with Diamond Brale Indenter; Part Number Hardness Value Scale Min Max Quick Ship; 9203-111: 25: HRC: 22.5: 27.5: 9203-121: 30 .Brinell Hardness HB: Rockwell C - HRC: Rockwell B - HRB: Vickers - HV : Enter a figure into any of the fields and click calculate, the nearest values in each scale is shown, or zero if out of range. Values are approximate and for guidance only. Reference Table: Steel hardness conversion chart - all values approximate.

rockwell model 1900 hardness tester

According to DIN EN IS 6508-1 the result of a Rockwell hardness test is depicted as follows: 60 HRC W ⇒ Rockwell hardness value. 60 HRC W ⇒ Generic marker for "Hardness Rockwell" 60 HRC W ⇒ Label for the hardness scale. 60 HRC W ⇒ Label for the material of the indenter in case a ball is used (not shown for diamond cone) HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness . 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C).

Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor .

Resultado da Amadores Club🔞. 3 999 subscribers. View in Telegram. Preview channel. If you have Telegram, you can view and join Amadores Club .

hardness tester hrc|roundness correction factors chart